The hull of a ship is the most notable structural entity of the ship. It is the watertight enclosure of the ship, which protects the cargo, machinery, and accommodation spaces of the ship from the weather, flooding, and structural damage.

Ship Hull Production typically comprised of following key processes:

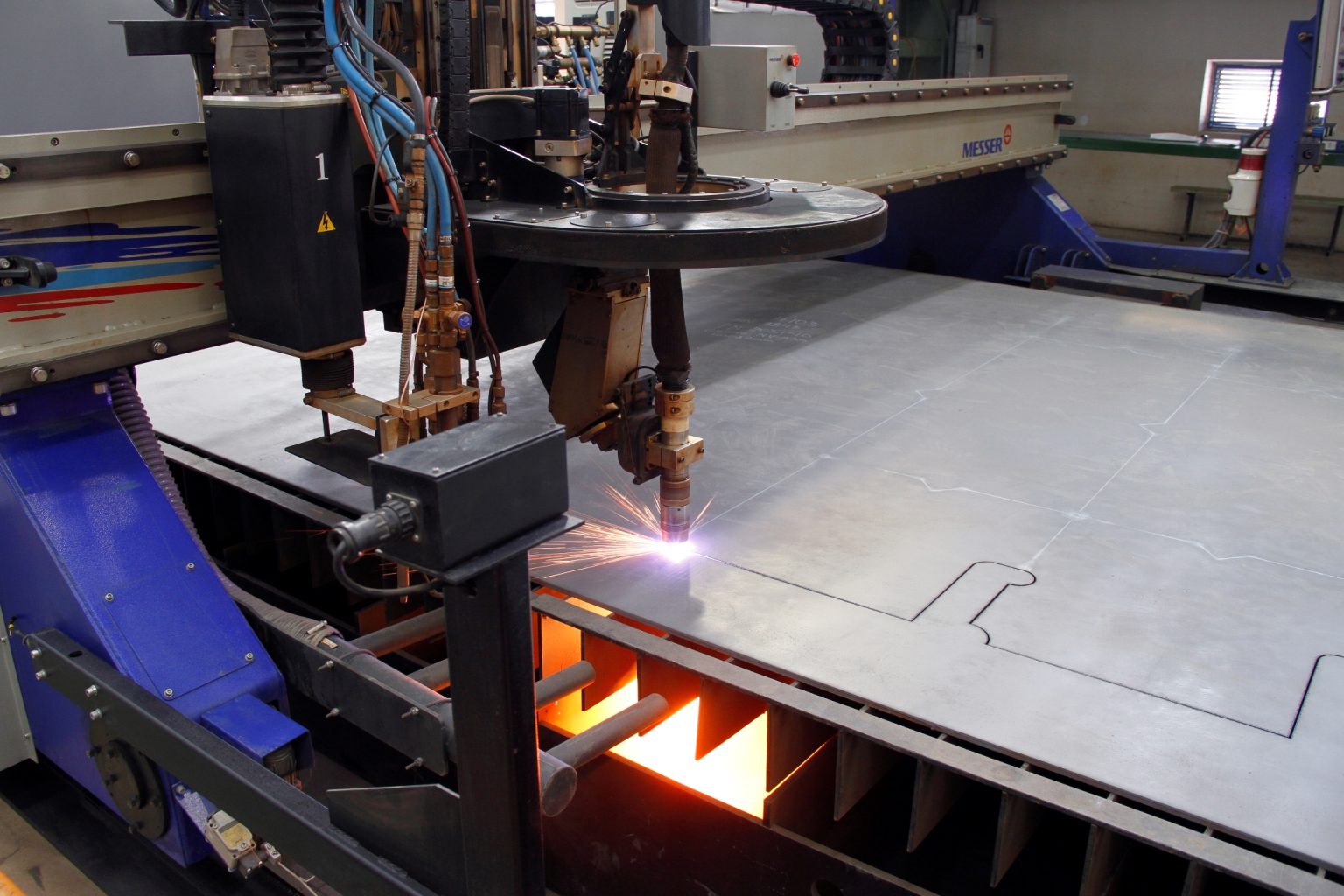

- Steel plate & profile cutting & forming

- Fabrication of panels

- Block Fabrication – Sub-Assembly

- Block Fabrication – Block Assembly

- Pre-outfitting

- Block erection

- Inspection and Testing

The Hull workshop is equipped with all the required machines and tools to execute metal construction works in high quality. Big steel constructions with complicated shapes are the daily business of Baku Shipyard’s workers. We are also equipped for metal construction works, ship repairs, and ship modifications.

- CNC Template Cutting Machine

- Nieland Pres Machine 500 T

- CNC Plasma Cutting Machine

- CNC Gas Cutting Machine

- One Side Welding Machine ( OSW )

- SMP (stiffener welding)

- SWP (stiffener welding)

- WMP (T bar fitting) (Web mounting portal)

- Service Portal Welding Machine

- Shearing Machine 3000 MM x 12 MM

Share this page